PRODUCT CENTER

The products distributed by our company are guaranteed by the manufacturer, and have a complete pre-sale, in-sale and after-sales service system. Our company has a strong standing stock of thousands of tons, sufficient supply and complete specifications. It has formed an annual inventory turnover of more than 9,000 tons and more than 800 specifications.

The fully automatic submerged arc welding production line's cutting, assembly and welding are all controlled by microcomputers to ensure that the dimensional accuracy of the H-shaped steel produced and the quality of the welds meet national standards.

High frequency welding H-shaped steel

The technical characteristics of high-frequency welding H-shaped steel are: (1) fast welding speed, which can reach 18-45m/min; (2) small thermal impact, easy to control the deformation of H-shaped steel; (3) H-shaped steel with different material combinations can be welded; (4) Micro-tension production can be achieved and welding stress can be reduced. Technical level: (1) High cross-sectional dimension accuracy; (2) Excellent cross-sectional performance; (3) Cross-sectional dimensions can be customized according to user requirements.

Classification of steel: According to the chemical composition, steel is divided into carbon steel and alloy steel; according to the use of steel, it can be divided into structural steel, tool steel and special performance steel.

Material: Carbon steel: 10#, 20#, 35#, 45#, S45C, 55#, Q235B, Q235C, Q345D, CF53, A105 Gold steel: 16Mn(0345B).20Cr40Cr15CrMo.20CrMo.28CrMo,30CrMo.35CrMo42CrMo.4130.414020 CrMnT.40MnMoV20Mn237Mn5ZF6.16MnCr5,20MnCr5.36Mn2V38Mn2V 20Mn2.65Mn.15Mo3Others: Special materials can be customized

Curtain Wall Right Angle Square Tube

The most outstanding feature of refined steel profiles is that they have the same surface flatness and straightness as aluminum profiles, and the outer R-angle is 90 degrees right angle. In glass curtain walls, under the same span conditions, the advantage of refined steel is that it can achieve a smaller volume and more flexible cross-section than aluminum profiles, achieving a more transparent lighting effect. Ordinary steel materials are mostly galvanized square tubes or hot-rolled rectangular steel tubes. They have a large R angle, rough appearance, insufficient straightness, and large bending deformation, so they cannot be used in high-quality glass curtain wall projects.

Specific drawings will differ and change. Some are like a "#" shape, with all sides coming out, some are like a "mouth", and of course there are also semi-sealed ones. Therefore, you must have drawings when processing box columns, and some also need to add some ribs and the like inside the columns.

The beam used to specifically load the crane inside the factory is called a crane beam. It is generally installed on the upper part of the factory building and functions together with the steel structure of the factory building.

Welded T-shaped steel: Made of tailor-welded steel strips, there are two welding processes. High-frequency welding is often used for plate thicknesses within 10MM, and submerged arc welding is generally used for plates above 10MM. Welded T-shaped steel is mainly used in electric power, curtain wall decoration, steel structure, shipbuilding, railway and other industries.

Special-shaped steel: Special-shaped steel is the abbreviation of complex and special-shaped section steel. It is a kind of section steel and is different from the name of simple section steel. According to different processes, it can be divided into hot-rolled special-shaped steel, cold-drawn (cold-drawn) special-shaped steel, cold-formed special-shaped steel, welded special-shaped steel, etc. Usually special-shaped steel refers specifically to hot-rolled special-shaped steel. Hot-rolled special-shaped steel is divided into square steel, round steel, flat steel and hot-rolled steel in common shapes.

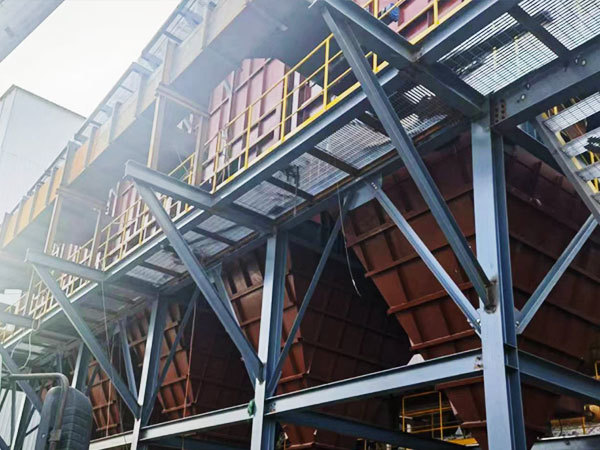

CASE DISPLAY

Project Cases

Project Cases

Project Cases

Project Cases

Project Cases

Project Cases

BAIXINXIN METAL MATERIALS (JINAN) CO., LTD.

Baixinxin Metal Materials (Jinan) Co., Ltd. is a professional steel structure company located in Jinan, focusing on providing customers with high-quality steel structure products and solutions. The company has its own professional team, including designers, engineers and technicians, who have rich experience and expertise and are able to provide customers with customized steel structure solutions.Baixinxin Metal Materials (Jinan) Co., Ltd. has advanced production equipment and technology and is able to produce steel structure products of various specifications and shapes according to customer needs. The company's products are widely used in industrial buildings, commercial buildings, bridges, large equipment supports and other fields, and are deeply trusted and praised by customers.

Founded

Annual Turnover Rate

More than 800 specifications

Exporting Country

NEWS CENTER

We have established cooperative relationships with steel manufacturers to obtain more technical support, which can perfectly meet customer requirements.

Advantages and characteristics of steel components

The steel component system has the comprehensive advantages of light weight, factory manufacturing, fast installation, short construction period, good seismic performance, fast investment recovery, and less environmental pollution. Compared with reinforced concrete structures, it is more "tall, large, and light" Due to the unique advantages of development in the three aspects, steel components have been reasonably and widely used in the field of construction engineering around the world, especially in developed countries and regions.

Bearing capacity of steel components

Practice shows that the greater the force, the greater the deformation of the steel component. However, when the force is too large, the steel components will break or undergo severe and significant plastic deformation, which will affect the normal operation of the engineering structure. In order to ensure that engineering materials and structures work normally under load, each steel component is required to have sufficient load-bearing capacity, also known as load-bearing capacity. The load-bearing capacity is mainly measured by the sufficient strength, stiffness and stability of the steel components.

04-26

2024

How to store T-shaped steel?

Stacking method: T-shaped steel should be stacked vertically, and the bottom should be flat and stable. Timbers should be placed between each layer to prevent deformation and damage. At the same time, they should be kept horizontally and vertically flat when stacked to avoid extrusion deformation at the bottom.

04-22

2024

T-shaped steel manufacturing process

T-shaped steel is a common structural steel with a T-shaped cross-section. It is widely used in construction, bridges, machinery manufacturing and other fields. The following introduces the manufacturing process of T-shaped steel.

04-15

2024

Application of box columns

Steel pipe columns are generally steel structural columns composed of one or more steel pipes. Box columns are steel structural columns composed of multiple steel sections (square and rectangular pipes, angle steel, channel steel, and I-beam steel).

04-08

2024

Performance advantages of box columns

It is conducive to the formation of an integrated structure between the earthquake-resistant floor and the exterior wall, which is conducive to waterproofing and can also be used as a civil defense basement, making full use of underground space.